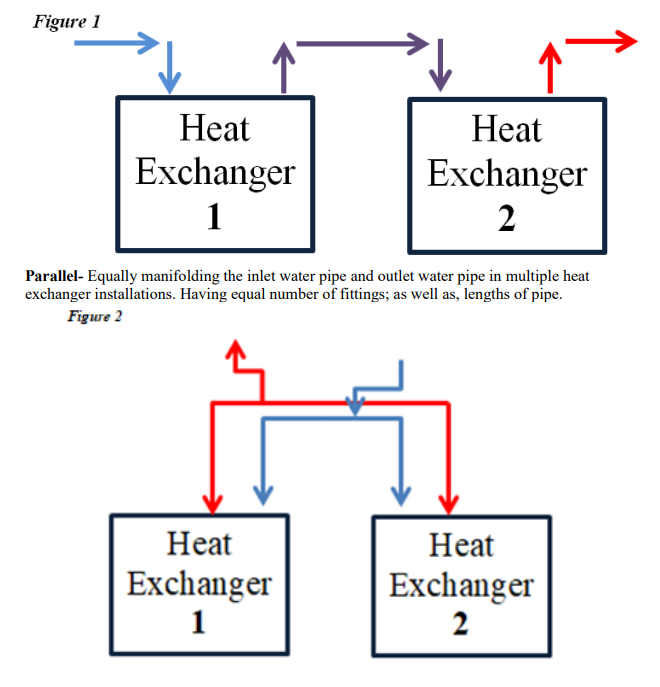

Understanding the difference in Parallel and Series Piping in Heat Exchangers

Comparison

Why shouldn’t I pipe in series?

When piping in series heat is absorbed by the cooling liquid in the first heat exchanger,

this causes the cooling liquid to be at a higher temperature when entering the second heat

exchanger and lowers its effective cooling capacity.

Why should I pipe in parallel?

Piping in parallel allows the same temperature liquid to enter both heat exchangers at the

same time. This allows both heat exchangers to utilize their effective cooling capacities.

Advantages of series pumps

Able to pump fluid from a low level to a relatively high level

- Low fluid flow rate

- Uneven heat dissipation throughout system

Advantages of parallel pumps

There is a limitation on pumping fluid from a low level to a relatively high level

- Low pressure may not be able to overcome static pressures of heat exchangers

- More piping is used, more complicated piping design